2020.08.26 Türkiye’s ethyl acetate plant was successfully started

Date:2020/08/26

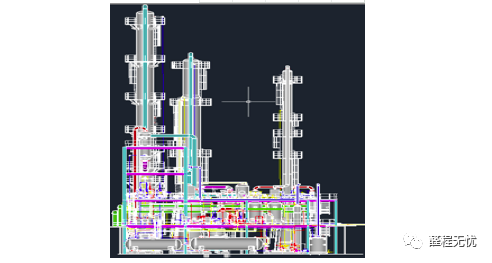

Hubei Sanli Liquidambar Technology Co., Ltd. is responsible for the 150 tons/day ethyl acetate refining EPC general contracting project in Turkey, including design, procurement, commissioning, operation, training, etc. After experiencing many difficulties such as the epidemic, we successfully produced qualified products and completed the load acceptance of the device. Let us review the progress of the device.

✮Sign the contract

The contract was officially signed in 2019.

✮Device advantages

This device adopts a three-tower thermal coupling energy-saving process and has the following advantages:

- Energy saving and environmental protection, far lower than the industry’s 1.6t/t steam consumption indicator;

- The device has great flexibility in load operation;

- High degree of self-control and simple operation;

- Use new catalysts;

- The process route is simple and the investment cost is low.

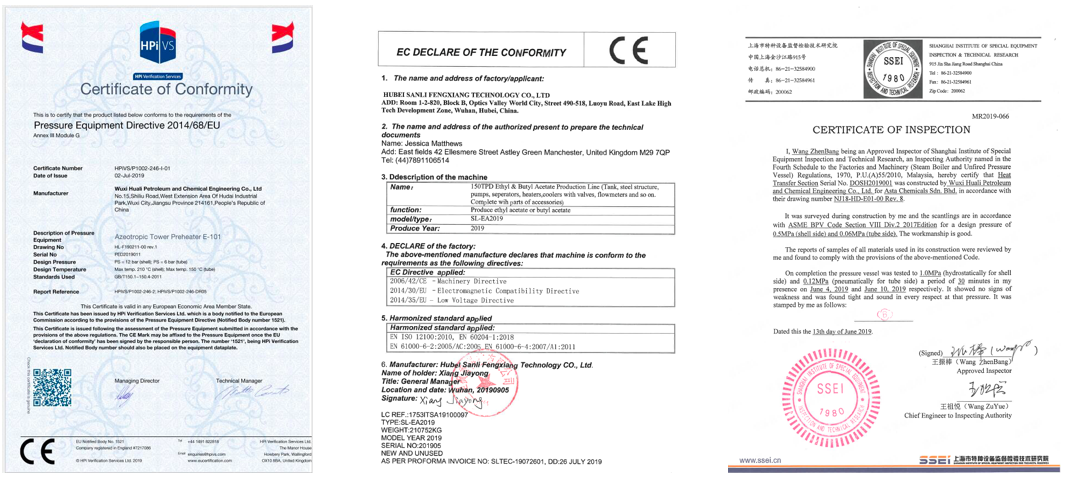

✮Purchasing and shipping

From August 2019 to October 2019, considering that this project is located in Turkey and is under the jurisdiction of the European Union, all equipment of this device has passed the EU CE certification and provided the EU CE certification certificate. Finally, a group of domestic companies with EU certification were selected. high-quality external suppliers.

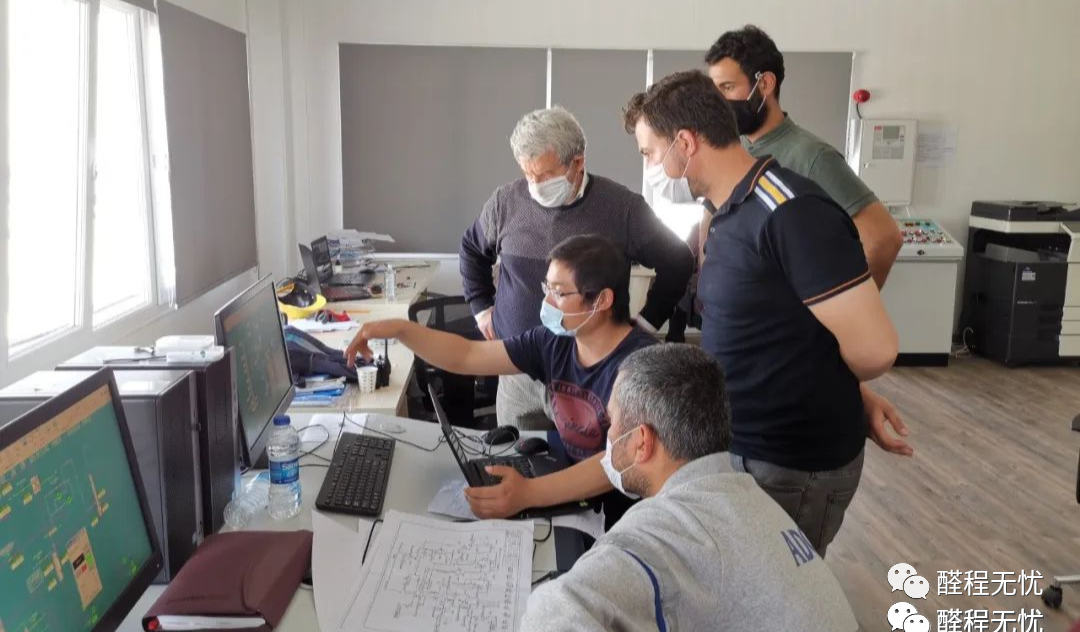

✮Installation and debugging

During the epidemic, engineers overcame difficulties and insisted on installation and commissioning training at the project site.

✮Run successfully

After the customer’s raw materials arrived at the site in August 2020, the device was successfully started in one go! The ethyl acetate product has reached the production standard and has been recognized and praised by customers!

The construction of this project will promote the development of the ethyl acetate deep processing industry in Turkey, which will help improve economic benefits, increase local employment opportunities, and create good social benefits.

I would like to thank our customers for their trust and support, the on-site engineers for their hard work, and every colleague of Sanli Liquidambar for working under heavy pressure to create another miracle!