- Technical introduction:

In the production process of paraformaldehyde and polyformaldehyde, high concentrations of formaldehyde are required as raw materials. However, in normal formaldehyde production, whether it is the silver method or the iron-molybdenum method, the product concentration does not exceed 55%. Therefore, the raw material formaldehyde needs to be dehydrated and concentrated, and dilute formaldehyde will be produced during the concentration process. Dilute formaldehyde is usually used to produce downstream products that do not require high concentration of formaldehyde raw materials (such as methenamine, methylal, etc.) and concentrated for recycling.

There are two commonly used dilute formaldehyde concentration and recovery technologies, namely the vacuum cyclone separation process and the pressure distillation concentration process. The former will produce about 8% dilute formaldehyde again during the concentration process; the latter can recover about 36-46% formaldehyde solution. However, during the pressurized distillation process, as the pressure increases, formaldehyde is prone to high-temperature oxidation. Formic acid will not only cause formaldehyde loss, but more importantly, formic acid will seriously corrode the distillation equipment, making it a major hidden danger that affects normal production. Although this problem can be solved by selecting higher-grade special steel, the investment will Too high and very uneconomical.

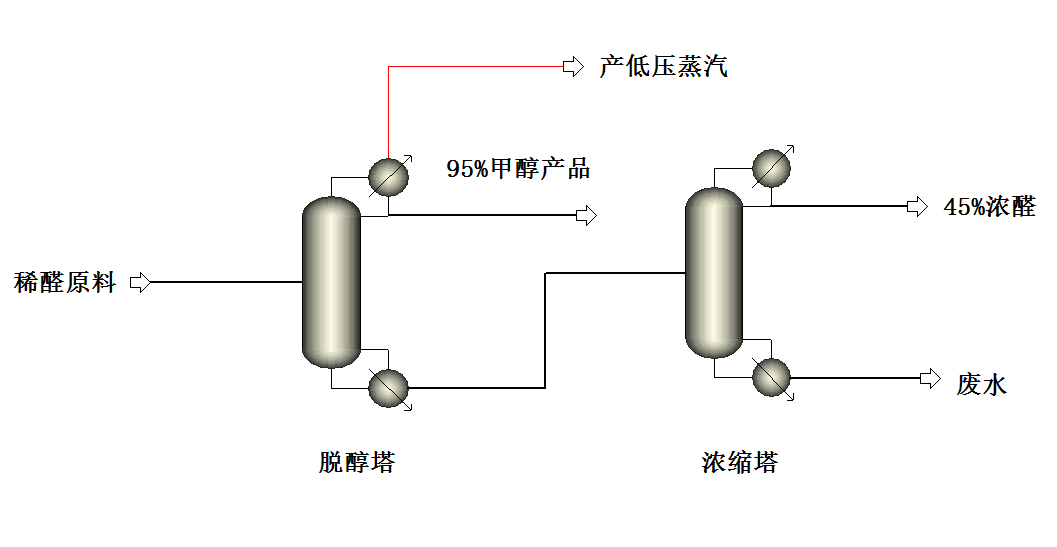

Our company’s dilute formaldehyde concentration and recovery technology is also based on pressurized distillation, using specially designed fillers as separation internals. It has high operating throughput and high efficiency, and the phenomenon of formic acid corrosion has relatively little impact. In addition, in order to reduce the methanol content in the formaldehyde product as much as possible, we set up a methanol separation tower to remove alcohol under reduced pressure before the dilute formaldehyde enters the concentration tower.

- Typical projects

A company’s 95 tons/day 22% dilute formaldehyde concentration recovery device

Processing capacity: 95 tons/day 22% dilute formaldehyde solution

Running time: 8000 hours/year

Operation flexibility: 80-120%

Raw material specifications: 22% dilute formaldehyde

| serial number | Element | unit | Specification |

| 1 | formaldehyde | % wt | ≈22 wt.% |

| 2 | Methanol | % wt | ≤3 wt.% |

| 3 | water | % wt | ≤78 wt.% |

| 4 | Formic acid | % wt | ≤0.08wt.% |

Product specifications:

| serial number | product | Specification | unit | Capacity |

| 1 | formaldehyde | See product-technical specifications | t/a | 15481 |

| 2 | Methanol | See product 2 technical specifications | t/a | 1000 |

Product 1 technical indicators: formaldehyde

| serial number | Element | unit | Specification,wt% |

| 1 | formaldehyde | % wt | ≥45 |

| 2 | water | % wt | ≤55 |

| 3 | Methanol | % wt | ≤0.5 |

| 4 | Formic acid | % wt | ≤0.1 |

Product two technical indicators: methanol

| serial number | Element | unit | Compositionwt% |

| 1 | Methanol | wt% | ≥95 |

| 2 | water | wt% | ≤5 |

Process consumption: (based on the production of 45% formaldehyde products per ton)

| serial number | Name | Specification | Consumption quota (t/t product) |

| 1 | Recycled water | 0.3MPag,32~40℃ | 2.28 |

| 2 | steam | 0.6 MPag | 38.8 |

| 3 | Industrial electricity | 380V,55hz | 12kWh/t |

| 4 | Formaldehyde raw materials | 22% formaldehyde | 2.3 |

Process flow diagram

Our company has been engaged in research and development in formaldehyde and its downstream fields for many years, and provides customers with customized dilute formaldehyde concentration and recovery technology all year round.